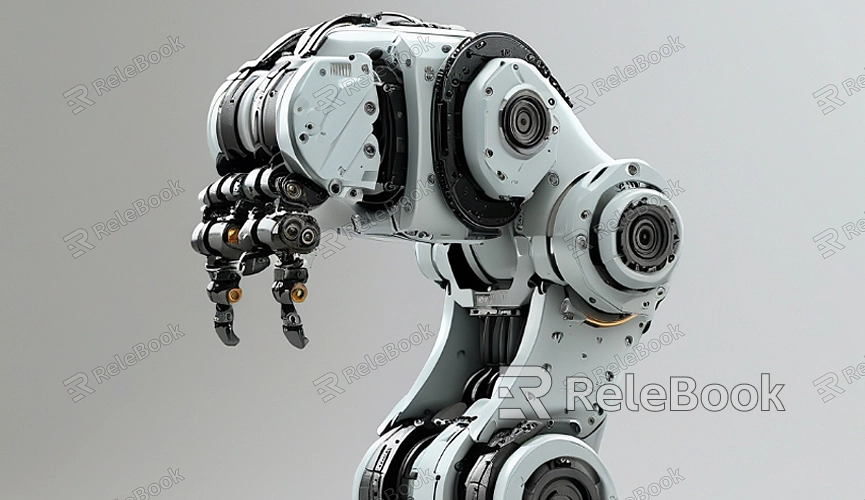

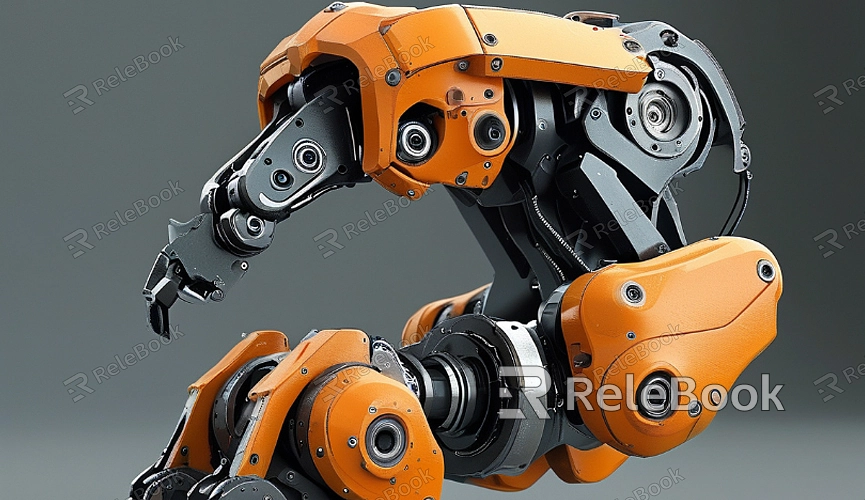

How to Model 3D Mechanical Joints?

In modern engineering design, mechanical joints are essential components used widely in robots, robotic arms, biomimetic designs, and many other fields. The advancement of 3D modeling technology allows us to create precise models for designing, testing, and optimizing the functionality and feasibility of mechanical joints. This article will explore how to model mechanical joints in 3D, covering common modeling methods, tool selection, important considerations in the modeling process, and practical tips.

Understanding the Basic Structure of Mechanical Joints

Before starting the modeling process, it's crucial to have a clear understanding of the basic structure and working principles of mechanical joints. The core function of a mechanical joint is to allow relative motion between two or more connected components, typically through rotation, sliding, or combined movement. In robotics and other mechanical systems, common types of joints include rotational joints, sliding joints, and ball-and-socket joints.

- Rotational Joints: These allow relative motion through rotation and are commonly used in robotic arms and other robotic systems.

- Sliding Joints: These allow relative motion through linear sliding, useful in systems that need to move along a straight line.

- Ball-and-Socket Joints: These provide multi-degree-of-freedom rotational motion and are typically used in designs requiring movement in all directions.

Once you understand the different joint types, you can choose the appropriate modeling methods and tools based on the specific needs of your project.

Selecting the Right Modeling Tools

The choice of modeling tools is crucial for successfully creating 3D models of mechanical joints. Several software options are available for mechanical modeling, with some specialized for mechanical design, offering more tools for simulating mechanical motion and precise geometric modeling. Common 3D modeling software includes:

- SolidWorks: Widely used in mechanical engineering, it is ideal for detailed part modeling and assembly design. Its motion analysis tools can simulate the dynamic behavior of mechanical joints.

- Fusion 360: An integrated platform that combines modeling, simulation, rendering, and manufacturing features, supporting cloud collaboration. It is great for mechanical part design and motion analysis.

- Blender: Although Blender is primarily used for animation and graphics, it has powerful modeling tools that are suitable for creating complex shapes, particularly useful for animated mechanical joints.

- CATIA: This software is used for complex product design in industries such as aerospace, automotive, and mechanical engineering, supporting advanced surface modeling and assembly design.

Each software has its unique features and use cases, so selecting the right tool can significantly improve modeling efficiency and reduce post-processing adjustments.

Design Approach and Modeling Process

When designing 3D models of mechanical joints, it's essential to begin with functionality, ensuring that the joint's movement meets real-world requirements. The modeling process should consider motion range, load-bearing capacity, material strength, and structural stability. Below is a general workflow for modeling mechanical joints:

1. Initial Concept and Sketch Design

Before formal modeling begins, an initial concept and sketch design are typically created. You can either hand-draw sketches or use design software for preliminary structure planning, determining the relative positions, motion directions, and connection methods of the components. In the sketching phase, focus more on the functional requirements than fine details.

2. Creating Basic Geometries

Using the sketch as a reference, the next step is to create the basic geometric shapes of the mechanical joint in the selected modeling software. Start with the simplest shapes, such as cubes, cylinders, or spheres, and refine them gradually. The goal at this stage is to establish the foundational framework for the joint.

3. Refining the Design and Adding Details

After the basic geometry is complete, you can refine the design by adding additional details, such as bearings, pins, support structures, etc. Depending on the joint type, it may also be necessary to apply kinematic constraints to the model to simulate real-world motion accurately.

4. Simulation and Testing

Once the model is completed, the next step is to test the motion using the software’s simulation tools. This ensures that the joint will move as intended, without collisions or other issues. If problems arise, the model can be adjusted accordingly until it meets the required specifications.

5. Rendering and Output

Finally, once the design is complete and has passed all simulations, rendering and output come next. High-quality renderings or animations can be generated to visualize the joint's real-world motion. In production, design files are typically exported in standard CAD formats like STL or STEP for further manufacturing or 3D printing.

Common Modeling Tips and Optimization Methods

During the 3D modeling process of mechanical joints, several tips and optimization techniques can help improve modeling efficiency and accuracy:

- Use Parametric Modeling: Many modern CAD programs support parametric design, where parameters control the size and shape of the model. Changing one parameter will automatically adjust other components, saving time and reducing manual adjustments.

- Avoid Over-Modeling: Over-complicating the model with unnecessary details can lead to increased complexity. It’s essential to simplify the design where possible while still meeting functional and aesthetic requirements.

- Consider Assembly and Compatibility: Throughout the modeling process, consider how the parts will fit together. Ensuring that all components are compatible and can be assembled correctly is vital, especially in designs involving multiple moving joints. Misalignments or assembly errors can affect the performance of the entire system.

3D modeling technology has greatly enhanced the design and optimization of mechanical joints, making the process more efficient and accurate. Whether in robotics, mechanical arms, or other automated systems, precise modeling of mechanical joints is crucial for improving performance and reliability. By following the guidance provided in this article, you should now have a clearer understanding of the mechanical joint modeling process. We hope this article inspires you in your design projects. For more high-quality 3D models and textures, feel free to visit the Relebook website to download resources suitable for your projects.

FAQ

How do I choose the right type of joint for 3D modeling?

The choice of joint type depends mainly on the functional requirements of the system. If rotation is needed, a rotational joint is ideal. For linear motion, a sliding joint works best. If multi-degree-of-freedom motion is required, a ball-and-socket joint may be the best choice. Analyzing the system's requirements will help guide the decision.

How can I ensure the joint does not collide during its motion in the modeling process?

Many modeling programs offer motion simulation tools to detect potential collisions. By setting motion limits and constraints in advance, you can ensure that the joint operates within its intended range without interference. If collisions occur, adjustments can be made to the design or motion path to eliminate the problem.

What should I focus on when modeling mechanical joints?

A3: Key considerations include the joint’s motion range, structural integrity, load-bearing capacity, and ease of assembly. Ensuring that each part fits and moves as intended is crucial to creating a functional and reliable mechanical joint. Material selection and strength are also essential factors to consider for durability.